LED Flower: Unterschied zwischen den Versionen

Marvin (Diskussion | Beiträge) |

Marvin (Diskussion | Beiträge) |

||

| Zeile 547: | Zeile 547: | ||

====LED Resistors==== | ====LED Resistors==== | ||

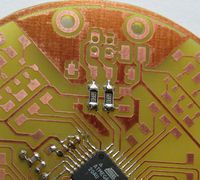

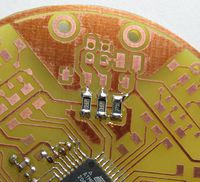

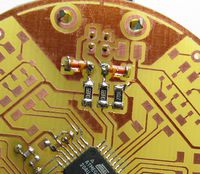

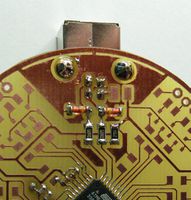

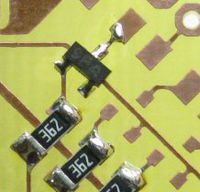

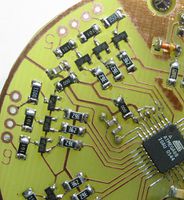

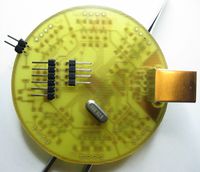

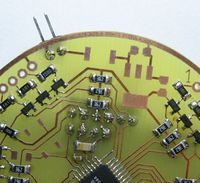

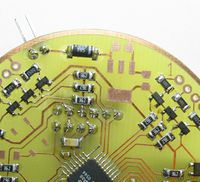

Next are the resistors that limit the current flow through the LEDs. If you are using the parts supplied at the 27C3 Peace Mission in Goettingen, you can just use the values given here. If you are using other LEDs, please calculate your own Values. First are the 150 Ω resistors R20 to R25 for the red LEDs. | Next are the resistors that limit the current flow through the LEDs. If you are using the parts supplied at the 27C3 Peace Mission in Goettingen, you can just use the values given here. If you are using other LEDs, please calculate your own Values. First are the 150 Ω resistors R20 to R25 for the red LEDs. Then the 150 Ω resistors R26 to R31 for the green and R32 to R37 for the blue LEDs are following: | ||

<gallery widths=200px heights=200px perrow=3> | <gallery widths=200px heights=200px perrow=3> | ||

Datei:Lf-0140-00.jpeg | Datei:Lf-0140-00.jpeg|The red resistors... | ||

Datei:Lf-0150-00.jpeg|...and red, green and blue. | |||

Datei:Lf-0150-00.jpeg | |||

</gallery> | </gallery> | ||

Version vom 25. Dezember 2010, 22:01 Uhr

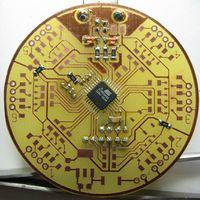

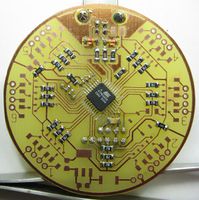

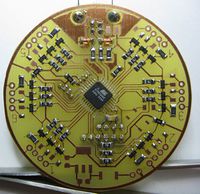

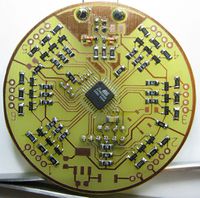

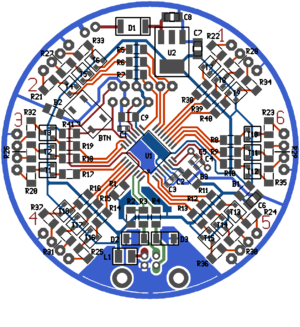

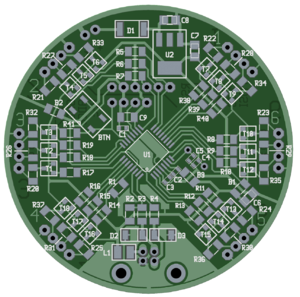

PCB

BOM

Necessary

| Designator | Value | Part-No | Price / EUR | Count | Sum / EUR |

|---|---|---|---|---|---|

| R1 | 3.6 kΩ, 1206 | R: | 0.01 | 1 | 0.01 |

| R2 | 2.7 kΩ, 1206 | R: | 0.01 | 1 | 0.01 |

| R3, R4 | 68 Ω, 1%, 1206 | CSD: 10-120068 | 0.01 | 2 | 0.02 |

| R5..R19, R38..R40 | 3.6 kΩ, 1206 | R: | 0.01 | 18 | 0.18 |

| R20..R31 | 100 Ω, 1206 | R: | 0.01 | 12 | 0.12 |

| R32..R37 | 150 Ω, 1206 | R: | 0.01 | 6 | 0.06 |

| B1..B3 | 0 Ω, 1206 | R: | 0.01 | 3 | 0.03 |

| T1..T18 | BC807-25, SOT23 | R: BC 807-25 SMD | 0.04 | 18 | 0.72 |

| C1, C2, C3 | 100 nF, 16 V, 0603 | R: X7R-G0603 100N | 0.05 | 3 | 0.15 |

| C4, C5 | 22 pF, 0603 | R: NPO-G0603 22P | 0.05 | 2 | 0.10 |

| C6 | 10 uF, 10 V, 0805 | R: X5R-G0805 10/16 | 0.07 | 1 | 0.07 |

| C9 | 100 nF, 63 V, 1206 | R: X7R-G1206 100N | 0.05 | 1 | 0.05 |

| D2, D3 | 3.6 V Zener Diode, MiniMELF | R: SMD ZF 3,6 | 0.05 | 2 | 0.10 |

| X1 | 20 MHz | R: 20,0000-HC49U-S | 0.18 | 1 | 0.18 |

| ISP, ADC, PWR | 12-pin break-away connector (from a 36-pin strip) | R: SL 1X36W 2,54 | 0.27 | 1 | 0.27 |

| CONN_USB | USB B connector | R: USB BW | 0.21 | 1 | 0.21 |

| U1 | ATmega88-20AU | R: ATMEGA 88-20 AU | 2.95 | 1 | 2.95 |

| LED1..LED6 | RGB LED | ? | 0.30 | 6 | 1.80 |

| 24 Copper wires | 40 cm copper wire cutoff | R: CUL 500/0,63 | 13.90 | 0.058 | 0.81 |

| Sum | 7.84 | ||||

Version 1: USB Powered

| Designator | Value | Part-No | Price / EUR | Count | Sum / EUR |

|---|---|---|---|---|---|

| L1 | 10 uH, 450 mA, 1210 | CSD: 146-121R010 | 0.22 | 1 | 0.22 |

| U2, C7, C8 | Do not populate | 0.00 | 0 | 0.00 | |

| Sum | 0.22 | ||||

Version 2: Externally powered

| Designator | Value | Part-No | Price / EUR | Count | Sum / EUR |

|---|---|---|---|---|---|

| U2 | LM1117-5.0 | CSD: LM1117DT-5,0V | 0.95 | 1 | 0.95 |

| C7, C8 | 10 uF, 10 V, 0805 | R: X5R-G0805 10/16 | 0.07 | 3 | 0.21 |

| D1 | 1N4001, MELF | R: X7R-G1206 100N | 0.04 | 1 | 0.04 |

| L1 | Do not populate | 0.00 | 0 | 0.00 | |

| Sum | 1.20 | ||||

Option: Button

| Designator | Value | Part-No | Price / EUR | Count | Sum / EUR |

|---|---|---|---|---|---|

| R41 | 3.6 kΩ, 1206 | R: | 0.01 | 1 | 0.01 |

| BTN | Pushbutton | ? | 0.10 | 1 | 0.10 |

| Sum | 0.11 | ||||

Tutorial

Soldering the Components onto the PCB

Microcontroller

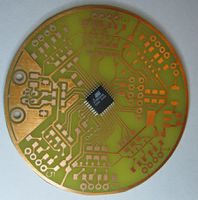

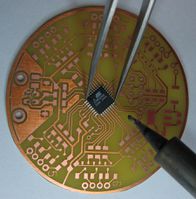

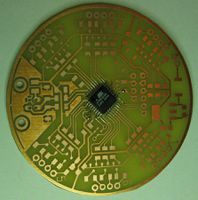

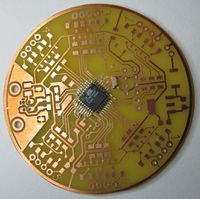

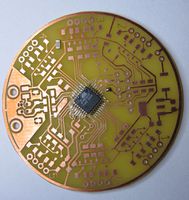

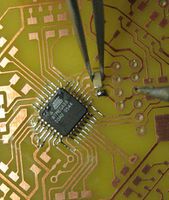

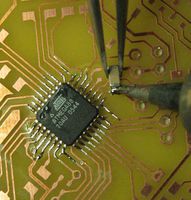

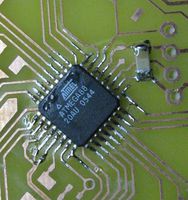

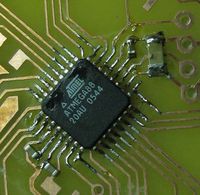

The first step in soldering this board is also the most difficult: Soldering the microcontroller. We are going to use the drag soldering technique. To do so, we first place the microcontroller on the board to get an idea of how it should be placed afterwards. Note the pin one mark which is a small dip in one corner of the IC. This is used to orient it correctly:

Now remove the microcontroller again, select one pad of the pcb and tin it. For this and the next two steps, you don't have to worry about any solder bridges, we will remove them afterwards.

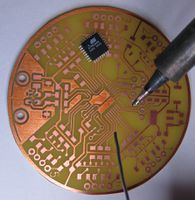

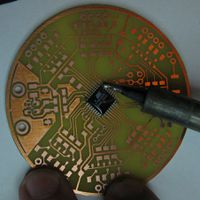

Now grab the microcontroller with a pair of tweezers, heat up the tinned pad and place the microcontroller correctly. Do not overheat the microcontroller: If you are not able to position the microcontroller within about 10 seconds remove the soldering iron and try again after waiting a short amount of time.

To further secure it, also solder one pin on the opposite corner.

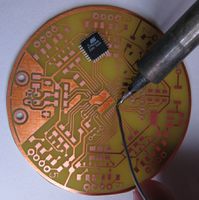

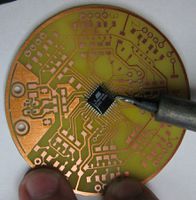

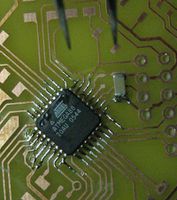

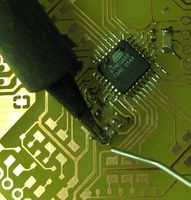

Now select one edge of the microcontroller that has not been used in the previous steps and add some Flux to pins. What comes now is not easy and probably may require multiple attempts: Solder some pins one on side of the edge at once and then just slide the soldering iron slowly and without any pressure to the other side:

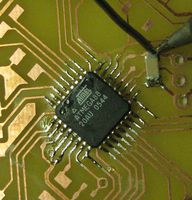

If you have done everything right (right speed, correct amound of solder and flux) all pins will be soldered to the board and there will be no bridges between them:

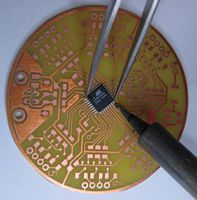

If you have created any bridges, there are two ways to get rid of them:

- Drag the solder away from the microcontroller.

- Use a desoldering gun or desoldering wig.

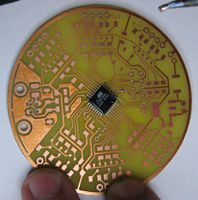

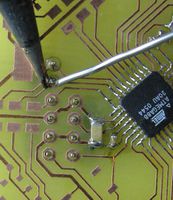

However, repeat this process for the three other edges that are not yet soldered completely:

Decoupling Capacitors

To operate, the microcontroller needs a set of decoupling capacitors. These are two-padded components, so we will esentially replicate the first steps of the microcontroller soldering process:

- Tin one pad,

- add the component and

- solder the other side.

The first one is C9, a 100 nF capacitor in a 1206 package, the biggest of the capacitors included in this kit:

Now continue with C1 using the same process. C1 is also a 100 nF capacitor, but in a 0603 package.

And now C2 and C3, both the same capacitor as C1.

Crystal Oscillator

Next step is the crystal oscillator. To prepare for that, we will first solder the capacitors C4 and C5 which are both 22 pf 0603 capacitors.

The crystal oscillator then goes directly on the other side of the pcb below those two capacitors. Just put it in and solder both pins.

-

Position of the Crystal

-

From the bottom

-

Solder both pins

Then clip off anything that is above the solder joint.

-

Clip off the excess wire

Programming and Analog Input Headers

Now we add two headers, one for programming the microcontroller, one for the analog input of the microcontroller. Again, the headers are on the back side of the PCB.

Now simply solder each pin to the PCB:

First Test

Get a lab power supply and set the maximum voltage to 5 V and the maximum current to zero. Connect the positive terminal (red) and negative terminal (black) as shown in the picture below:

-

The positive terminal goes to the leftmost pin of the shorter connector, the negative terminal to the middle one of the remaining three pins.

Slowly increase the current. The current should not exceed 20 mA.

If you have reached 20 mA, but the voltage is still below the previously set voltage limit, there is something wrong. Do not further increase the current limit as this could damage the device. Check if every component is soldered and oriented correctly, check if there are any solder bridges.

If everything is okay, connect the in-system programmer. From left to right it's: MOSI, MISO, SCK, Vcc, GND, /RESET

Programming the Microcontroller's Fuses

Go into the source folder and execute make fuses:

source$ make fuses

avrdude -c avrispmkII -P usb -B 100 -p m88 -U lfuse:w:0xff:m -U hfuse:w:0xdf:m -U efuse:w:0xf9:m

avrdude: AVR device initialized and ready to accept instructions

Reading | ################################################## | 100% 0.02s

avrdude: Device signature = 0x1e930a

avrdude: reading input file "0xff"

avrdude: writing lfuse (1 bytes):

Writing | ################################################## | 100% 0.01s

avrdude: 1 bytes of lfuse written

avrdude: verifying lfuse memory against 0xff:

avrdude: load data lfuse data from input file 0xff:

avrdude: input file 0xff contains 1 bytes

avrdude: reading on-chip lfuse data:

Reading | ################################################## | 100% 0.00s

avrdude: verifying ...

avrdude: 1 bytes of lfuse verified

avrdude: reading input file "0xdf"

avrdude: writing hfuse (1 bytes):

Writing | ################################################## | 100% 0.00s

avrdude: 1 bytes of hfuse written

avrdude: verifying hfuse memory against 0xdf:

avrdude: load data hfuse data from input file 0xdf:

avrdude: input file 0xdf contains 1 bytes

avrdude: reading on-chip hfuse data:

Reading | ################################################## | 100% 0.00s

avrdude: verifying ...

avrdude: 1 bytes of hfuse verified

avrdude: reading input file "0xf9"

avrdude: writing efuse (1 bytes):

Writing | | 0% 0.00s ***failed;

Writing | ################################################## | 100% 0.05s

avrdude: 1 bytes of efuse written

avrdude: verifying efuse memory against 0xf9:

avrdude: load data efuse data from input file 0xf9:

avrdude: input file 0xf9 contains 1 bytes

avrdude: reading on-chip efuse data:

Reading | ################################################## | 100% 0.00s

avrdude: verifying ...

avrdude: verification error, first mismatch at byte 0x0000

0xf9 != 0x01

avrdude: verification error; content mismatch

avrdude: safemode: efuse changed! Was f9, and is now 1

Would you like this fuse to be changed back? [y/n] n

avrdude: safemode: Fuses OK

avrdude done. Thank you.

make: *** [fuses] Error 1

If you are asked if you want to change back the efuse as it has not been written correctly, just say 'n'. In fact the fuse has probably been written correctly, the upper bits are just not writable and always remain 1.

To program the microcontroller and check if the oscillator is working, just execute make:

source$ make

Building objects build/base.o build/usb.o build/leds.o build/usbdrv/usbdrv.o build/usbdrv/oddebug.o build/usbdrv/usbdrvasm.o -> build/out.elf -> build/out.hex

make build/out.hex

make[1]: Entering directory `source'

avr-gcc -std=gnu99 -W -Wall -pedantic -DF_CPU=20000000UL -mmcu=atmega88 -O2 -ffreestanding -Wl,--relax -c src/base.c -o build/base.o

avr-gcc -std=gnu99 -W -Wall -pedantic -DF_CPU=20000000UL -mmcu=atmega88 -O2 -ffreestanding -Wl,--relax -c src/usb.c -o build/usb.o

avr-gcc -std=gnu99 -W -Wall -pedantic -DF_CPU=20000000UL -mmcu=atmega88 -O2 -ffreestanding -Wl,--relax -c src/leds.c -o build/leds.o

avr-gcc -std=gnu99 -W -Wall -pedantic -DF_CPU=20000000UL -mmcu=atmega88 -O2 -ffreestanding -Wl,--relax -c src/usbdrv/usbdrv.c -o build/usbdrv/usbdrv.o

src/usbdrv/usbdrv.c:115: warning: overflow in implicit constant conversion

src/usbdrv/usbdrv.c:154: warning: overflow in implicit constant conversion

src/usbdrv/usbdrv.c:156: warning: overflow in implicit constant conversion

src/usbdrv/usbdrv.c: In function ‘usbHandleResetHook’:

src/usbdrv/usbdrv.c:550: warning: unused parameter ‘notResetState’

avr-gcc -std=gnu99 -W -Wall -pedantic -DF_CPU=20000000UL -mmcu=atmega88 -O2 -ffreestanding -Wl,--relax -c src/usbdrv/oddebug.c -o build/usbdrv/oddebug.o

avr-gcc -std=gnu99 -W -Wall -pedantic -DF_CPU=20000000UL -mmcu=atmega88 -O2 -ffreestanding -Wl,--relax -c src/usbdrv/usbdrvasm.S -o build/usbdrv/usbdrvasm.o

avr-gcc -std=gnu99 -W -Wall -pedantic -DF_CPU=20000000UL -mmcu=atmega88 -O2 -ffreestanding -Wl,--relax build/base.o build/usb.o build/leds.o build/usbdrv/usbdrv.o build/usbdrv/oddebug.o build/usbdrv/usbdrvasm.o -o build/out.elf

avr-size build/out.elf

text data bss dec hex filename

1862 2 65 1929 789 build/out.elf

avr-objcopy -R .eeprom -O ihex -v build/out.elf build/out.hex

copy from `build/out.elf' [elf32-avr] to `build/out.hex' [ihex]

make[1]: Leaving directory `source'

make flash

make[1]: Entering directory `source'

avrdude -c avrispmkII -P usb -B 1 -p m88 -U flash:w:build/out.hex:i

avrdude: AVR device initialized and ready to accept instructions

Reading | ################################################## | 100% 0.00s

avrdude: Device signature = 0x1e930a

avrdude: NOTE: FLASH memory has been specified, an erase cycle will be performed

To disable this feature, specify the -D option.

avrdude: erasing chip

avrdude: reading input file "build/out.hex"

avrdude: writing flash (1864 bytes):

Writing | ################################################## | 100% 0.20s

avrdude: 1864 bytes of flash written

avrdude: verifying flash memory against build/out.hex:

avrdude: load data flash data from input file build/out.hex:

avrdude: input file build/out.hex contains 1864 bytes

avrdude: reading on-chip flash data:

Reading | ################################################## | 100% 0.10s

avrdude: verifying ...

avrdude: 1864 bytes of flash verified

avrdude: safemode: Fuses OK

avrdude done. Thank you.

make[1]: Leaving directory `source'

USB Port

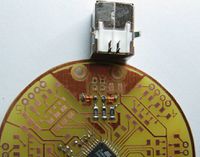

Solder R2, R3, R4, D2, D3 and the USB connector as shown below.

Testing the USB Port

Let's test the USB port. However, note that this port does not follow the USB specifications and could damage your computer. There are at least two ways to prevent this: 1. First connect the device to a hub that is not connected to the Host and see what happens. Then connect your Host to the Hub. 2. Even better would be to add a USB isolator as the one used below.

After connecting the Device to your Host, you should get a notification about a new USB device:

trottel kernel: [76212.960126] usb 1-4.3.2: new low speed USB device using ehci_hcd and address 59

When you see this line, the tricky part of this Workshop is done. :)

Finishing the PCB's Core

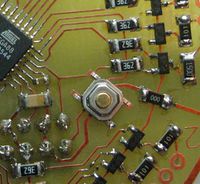

Just to improve some electromagnetic emissions, add bridges (or 0 Ohm Resistors) B1, B2 and B3.

Base & Reset Resistors

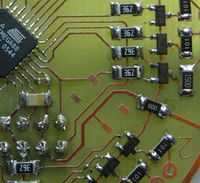

Now we are going to add the /Reset pullup resistor R1 and base resistors R8 to R19 and R38 to R40 with 3.6 kΩ resistors

Transistors

Now we are adding the transistors T1 to T18 (BC807).

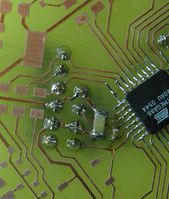

LED Resistors

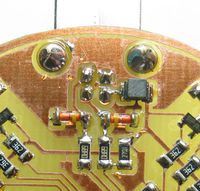

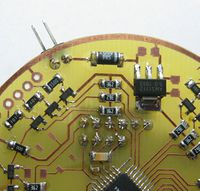

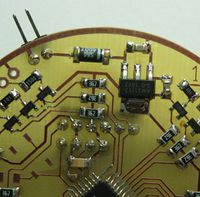

Next are the resistors that limit the current flow through the LEDs. If you are using the parts supplied at the 27C3 Peace Mission in Goettingen, you can just use the values given here. If you are using other LEDs, please calculate your own Values. First are the 150 Ω resistors R20 to R25 for the red LEDs. Then the 150 Ω resistors R26 to R31 for the green and R32 to R37 for the blue LEDs are following:

-

The red resistors...

-

...and red, green and blue.