Drawdio: Unterschied zwischen den Versionen

Marvin (Diskussion | Beiträge) |

Marvin (Diskussion | Beiträge) |

||

| Zeile 49: | Zeile 49: | ||

===Preparing the Pencil=== | ===Preparing the Pencil=== | ||

Get a very fine saw and saw into your pencil until you see the pencil's lead. Tilt the saw about 45 degrees and remove some additional wood from the pencil. Make sure that the lead is completely accessible. | |||

===Adding the Lead Contact=== | |||

Grab a piece of silver enameled wire and insert it into the PCB as shown in the following pictures. Make sure that the wire is at least this large and though it may be a bit larger, it should not be very much. | |||

[[Category:Projekte]] | [[Category:Projekte]] | ||

[[Category:Bausaetze]] | [[Category:Bausaetze]] | ||

Version vom 12. Mai 2012, 20:25 Uhr

This Drawdio is a clone of the famous Drawdio by Jay Silver. This design is optimized to be cheap enough and have a component orientation that makes soldering quite easy, so you can train soldering SMT components for the first time. This the Drawdio accompanies our SMT soldering workshop.

Schematic

Getting the Design Data

You can checkout the git repository with the gschem schematics and geda pcb board file:

git clone http://www.0x53a.de/git/drawdio

Building Tutorial

555 Timer

We start with soldering the 555 Timer IC. For this, first think about how it has to be placed on the PCB. The area should be relatively easy to determine, you can do this either by the form of the pads where the legs will be soldered to or by the name: The place is marked "U1".

Then the orientation of this device is important. You can see a notch on the IC marker on the PCB. On the IC this side is also marked, for example by a dot or a thick line.

- Now add a little bit of tin to the upper left pad on PCB. Do this by heading up the pad with your soldering iron and then applying tin to the pad, not the tip.

- Grab the IC with your tweezers in your lead hand. Grab the soldering iron with your other hand. Heat up the pad you just added solder to and then place the IC correctly onto the PCB. It should now be held in place by the one solder joint, even if this joint does not look very nice right now.

- Solder all other joints, one by one.

- Heat up the first joint and add a little bit of solder. The joint should then look nice and shiny.

Rectifier Diode

To protect your drawdio from anybody who tries to insert the battery in reverse, add a diode of type 4N400x (wher the x can be anything from 1 to 7). Again, the place is marked with D1. On the PCB, you will also see a diode sign. This sign can be decomposed into a triangle and a single line. The diode is correctly aligned if the single line of the diode symbol is on the same side as the line marker on the diode itself.

Go forth as last time. Add solder to one pad. Grab the diode into your lead hand, heat up the solder and place the diode. Then solder the other side of the diode. Afterwards, resolder the first joint.

Timing Capacitor

Now we add the timing capacitor. This capacitor can be anything from 200 to 1000 pF. A greater capacitance will tune your drawdio to oscillate at lower frequencies. The capacitor should be soldered to the place marked as C2. The orientation is irrelevant, as are all orientations of the remaining SMT components we solder in this tutorial.

Decoupling and Blocking Capacitors

Now we need some 100 nF capacitors. They belong to C1, C3 and C4. Use the same method as previously to solder them.

Timing Resistors

At last we solder the resistors that determine the timing operation of the 555. Add a 10k Resistor to R1 and a 300k Resistor to R2 using the established method.

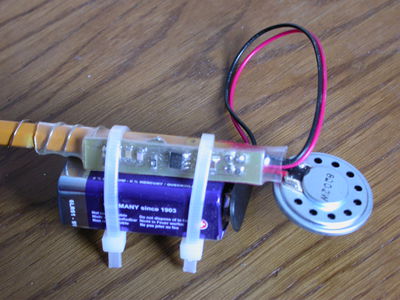

Battery Connector

Add the batter connector to the two pins labeled "PWR". The black (or negative) lead of the connector goes into the hole with the round pad. The red (or positive) lead belongs into the hole with the quadratic pad.

Speaker wiring

Take two pieces of wire, for example a red and a black one. They should be about 4 cm in lengths. Remove the isolation on both sides of each wire for about 3mm. Twist the strands of the wire at each end and apply some solder to it. Then apply some solder to each leg of the speaker.

Join the long leg with one end of the red wire by heating up the speaker pin and holding the red wire to it. Do the same with the black wire and the short leg.

You should now have a speaker with two wires, a black and a red one. Solder these to the PCBs at the SPEAKER connector. The correct positions for black and red are marked on the back side of the PCBs with "black" and "red". Alternatively: The red one belongs into the hole with the square pad and the black one into the hole with the round pad. Solder them there.

Preparing the Pencil

Get a very fine saw and saw into your pencil until you see the pencil's lead. Tilt the saw about 45 degrees and remove some additional wood from the pencil. Make sure that the lead is completely accessible.

Adding the Lead Contact

Grab a piece of silver enameled wire and insert it into the PCB as shown in the following pictures. Make sure that the wire is at least this large and though it may be a bit larger, it should not be very much.